© BOPP Patrick 2000 - 2025

The joy of playing with initially well running locomotives does not always remain undimmed. In some

locomotives in particular, damage to the gearbox occurs over the years, even though the hobbyist has handled

his vehicles with care and has even not used them for a long time.

Who hasn't experienced this?

At some point, you've bought a locomotive and, of course, let it run. Everything's fine, it runs perfectly and

beautifully, just as it's almost typical for American machines and as is generally the case for locomotives in this

category. In short, you are satisfied with the purchase. After a year or two, the moment comes when you want

to use it again. But now comes the scary moment: you put it on the tracks and are shocked by the terrible

driving behavior: the locomotive no longer runs as smoothly as it did at the beginning, but instead it hobbles,

makes a terrible noise and has almost no tractive power anymore. The hobbyist will initially suspect power

pickup problems, clean the locomotive and rail, but there is no success. Lack of lubrication? But after clipping

off the floor cover on the bogies, you notice that everything there is floating in grease, so everything is OK?

The layer of fat makes it almost impossible to identify the origin of the problem at first, because it's in the gears!

One or more of them have cracks that are the cause of the poor driving behavior. Tooth by tooth Once you have

found the basic fault, you can then easily start to fix it. But knowing the cause is also quite interesting. The

transmission pinions of the drive axles were made of plastic at one time and this has the property of becoming

brittle after a while if it is not used regularly. Partly this is due to the plasticizer and/or the material. If you want to

use the locomotive again after a long period, the plastic gear(s) tend to burst. This longitudinal crack affects the

distance between the teeth; if there is a gap, they can no longer mesh well or slip through .The defective spot

sometimes comes together tooth to tooth and the machine hops as a result. You can also recognize the fault by

a slight, dull impact. Today these pinions are made of softer Teflon and the problem of them becoming brittle

due to drying no longer exists. This short description is valid for both new and used material.

The solution to the problem is to replace these pinions. You can purchase it from a good American model

railway dealer. There are two variants, once the pinion alone and once the entire axle. If you place the

locomotive backwards in a locomotive bed, you can see a cover on the bogies (picture 1), which extends over

the entire length. This must be lifted and removed very carefully with a fine slotted screwdriver. Then the axles

with the plastic pinions are presented to you. You lift them very carefully out of the holder and pull the two

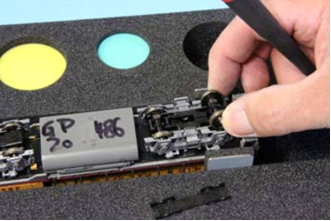

halves of the axle apart, (picture 2), removing the gear from its counterpart. It is important to ensure that the two

brass squares on the outside of the pinion do not get lost. They have the function of passing on the current from

the wheels to the power strip on the side. Now that the various parts of the axle are on the table, you can

replace the defective gear with the new one. Then check the track width using a gauge or on a piece of track

and you can reinsert the whole thing. But be careful, inserting, it requires a bit of patience (picture 3), as the

brass blocks don't always want to slide into place right away. Then you have to help with tweezers. Once the

axles are back in their place, you should let a drop of oil or grease (really just a drop) run into the new pinion.

Then you clip the cover plate on again very carefully. Once, new parts have been brought together with old

parts, it is a good idea to let the locomotive run in both directions again for at least a quarter of an hour. Once

this has been done, you can have fun again, playing with the locomotive.

HOPPY LOCOMOTIVE

The replacement gears can be purchased as universal spare parts from model railway dealers (with an American range)

or from the respective locomotive manufacturer.

PICTURE-2

The stub axles with the brass blocks are pulled along

Remove the damaged gear using gentle force

PICTURE-1

Use a smaller slotted screwdriver to spread them apart

The locking lugs on the bogie move slightly outwards and lift

the cover up at the same time.

PICTURE-3

When you put the axle back in, the brass pieces tend to move a

little sideways. You have to correct something with tweezers or a

screwdriver.

© Irure ut pariatur ad ea in ut in et. In incididunt sed tempor

The joy of playing with initially well running

locomotives does not

always remain

undimmed. In some

locomotives in

particular, damage to

the gearbox occurs

over the years, even

though the hobbyist

has handled his

vehicles with care and

has even not used

them for a long time.

Who hasn't

experienced this?

At some point, you've bought a locomotive

and, of course, let it run. Everything's fine, it

runs perfectly and beautifully, just as it's

almost typical for American machines and as

is generally the case for locomotives in this

category. In short, you are satisfied with the

purchase. After a year or two, the moment

comes when you want to use it again. But now

comes the scary moment: you put it on the

tracks and are shocked by the terrible driving

behavior: the locomotive no longer runs as

smoothly as it did at the beginning, but instead

it hobbles, makes a terrible noise and has

almost no tractive power anymore. The

hobbyist will initially suspect power pickup

problems, clean the locomotive and rail, but

there is no success. Lack of lubrication? But

after clipping off the floor cover on the bogies,

you notice that everything there is floating in

grease, so everything is OK?

The layer of fat makes it almost impossible to

identify the origin of the problem at first,

because it's in the gears! One or more of them

have cracks that are the cause of the poor

driving behavior. Tooth by tooth Once you

have found the basic fault, you can then easily

start to fix it. But knowing the cause is also

quite interesting. The transmission pinions of

the drive axles were made of plastic at one

time and this has the property of becoming

brittle after a while if it is not used regularly.

Partly this is due to the plasticizer and/or the

material. If you want to use the locomotive

again after a long period, the plastic gear(s)

tend to burst. This longitudinal crack affects

the distance between the teeth; if there is a

gap, they can no longer mesh well or slip

through .The defective spot sometimes comes

together tooth to tooth and the machine hops

as a result. You can also recognize the fault by

a slight, dull impact. Today these pinions are

made of softer Teflon and the problem of them

becoming brittle due to drying no longer

exists. This short description is valid for both

new and used material.

The solution to the problem is to replace these

pinions. You can purchase it from a good

American model railway dealer. There are two

variants, once the pinion alone and once the

entire axle. If you place the locomotive

backwards in a locomotive bed, you can see a

cover on the bogies (picture 1), which extends

over the entire length. This must be lifted and

removed very carefully with a fine slotted

screwdriver. Then the axles with the plastic

pinions are presented to you. You lift them

very carefully out of the holder and pull the

two halves of the axle apart, (picture 2),

removing the gear from its counterpart. It is

important to ensure that the two brass squares

on the outside of the pinion do not get lost.

They have the function of passing on the

current from the wheels to the power strip on

the side. Now that the various parts of the axle

are on the table, you can replace the defective

gear with the new one. Then check the track

width using a gauge or on a piece of track and

you can reinsert the whole thing. But be

careful, inserting, it requires a bit of patience

(picture 3), as the brass blocks don't always

want to slide into place right away. Then you

have to help with tweezers. Once the axles

are back in their place, you should let a drop

of oil or grease (really just a drop) run into the

new pinion. Then you clip the cover plate on

again very carefully. Once, new parts have

been brought together with old parts, it is a

good idea to let the locomotive run in both

directions again for at least a quarter of an

hour. Once this has been done, you can have

fun again, playing with the locomotive.

- Pos 1

- Shop

- Shop-a

- Shop-a

- Shop-usa-billboards-horizontal-a

- Shop-billboards-b

- Shop-panneaux-publicitaire-a

- News

- Howto-a

- Tarpolin-a

- Tarpolin-b

- Tarpolin-fs

- Activ-a

- GALERIE

- Galery-a

- Self made-a

- Flatcars-a

- Boxcar-a

- Gondola-a

- Contact-a

- Rost-a

- Rust-a

- Hoppelloks-a

- Hoppelloks-a

- Hoppy locomotive-a

- Locomotive instable-a

- Ironscrap gondola-a

- Carweight-a

- Carweight-a

- Poids wagon-a

- Fototransfer-a

- Fototransferfr-a

- Fototransferen-a

- About

- Contact-a

- Contact-a

- Contact-a